What are the process characteristics of acrylic board? Hardness is one of the parameters that reflects the production process and technology of cast acrylic sheets, as well as their high temperature resistance.

1. The hardness directly affects whether the board shrinks, bends, and deforms, as well as whether the surface cracks during the processing. The hardness of acrylic board is one of the hard indicators to measure the quality of acrylic board, with an average hardness of 8 or 9 degrees.

2. Thickness (Acrylic Tolerance) Acrylic plate thickness has an acrylic tolerance, so the control of acrylic tolerance is an important embodiment of quality management and production technology. The production of acrylic has the tolerance requirements of the international standard GB7134 for cast plates: the tolerance for 3mm thick acrylic plates is ± (0.4mm)

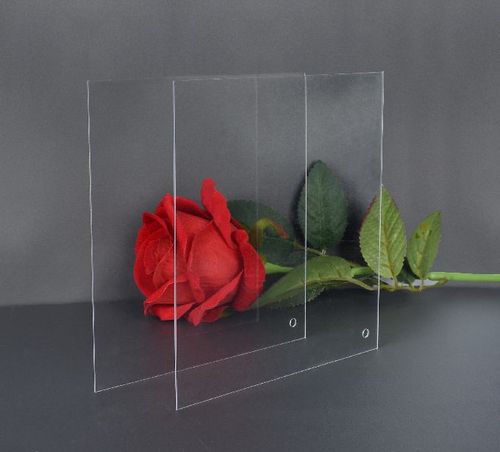

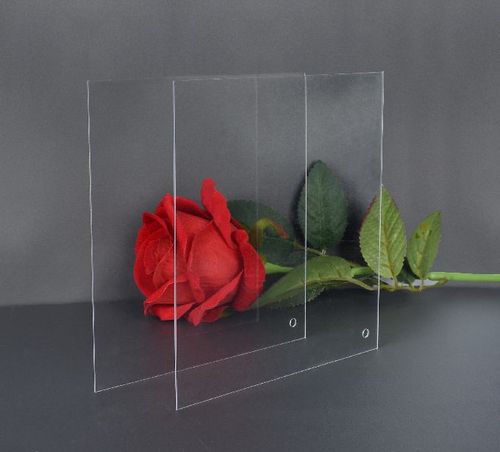

3. The transparency of acrylic panels, selection of raw materials, advanced formula follow-up, and modern production processes ensure that the panels have good transparency.

4. Process characteristics: Acrylic board has weather resistance and obvious moisture absorption. Acrylic plate has effective and obvious Non-Newtonian fluid characteristics in the range of forming temperature. As the shear rate increases, the viscosity of the melt will significantly decrease, and the viscosity of the melt is also very sensitive to temperature changes. Therefore, for the forming process of acrylic plates, increasing the forming pressure and temperature can significantly reduce the melt viscosity and achieve better fluidity. The acrylic plate begins to flow at around 160 ℃ and decomposes above 270 ℃, with a wide processing temperature range. Acrylic plates have high melt viscosity, fast cooling speed, and are prone to internal stress in the product. Therefore, strict control of process conditions is required during the molding process, and post-processing is also required after the product is formed. Acrylic board is an amorphous polymer with a small shrinkage rate and variation range, generally around 0.5% -0.8%, which is beneficial for forming plastic parts with high dimensional accuracy. Acrylic boards have excellent cutting performance, and their contours can be easily machined into various required sizes.

5. It has crystal transparency, transmittance greater than 92%, soft light, clear vision, and good color rendering effect using acrylic color plates. Acrylic board has excellent weather resistance, high surface hardness and luster, as well as good high-temperature performance. Acrylic plate has good processing performance and can be Thermoforming or machined. Transparent acrylic panels have a higher transmittance than glass, but their density is only half that of glass. Moreover, it is not as fragile as glass. Even if it is damaged, it will not form sharp fragments like glass. The wear resistance of acrylic board is similar to that of aluminum, with good stability and resistance to corrosion from various chemicals. Acrylic board has good printability and spray resistance. Use appropriate printing and spraying processes.

During processing, due to the very fast cooling speed of the acrylic board and the fact that it takes more than ten seconds to shape at room temperature, those who want to customize the shape need to strictly control the temperature.

During processing, due to the very fast cooling speed of the acrylic board and the fact that it takes more than ten seconds to shape at room temperature, those who want to customize the shape need to strictly control the temperature.

During processing, due to the very fast cooling speed of the acrylic board and the fact that it takes more than ten seconds to shape at room temperature, those who want to customize the shape need to strictly control the temperature.

During processing, due to the very fast cooling speed of the acrylic board and the fact that it takes more than ten seconds to shape at room temperature, those who want to customize the shape need to strictly control the temperature.